Hermetic feedthroughs are essential components in electronics, aerospace, medical, and industrial systems, providing reliable pathways for electrical, optical, or fluid connections while maintaining airtight or vacuum integrity. While their performance is critical, cost is often a key consideration for engineers and procurement teams. Understanding the factors that influence hermetic feedthrough pricing can help you budget effectively. Trusted brands like PAVE Technology provide high-quality feedthroughs that balance performance and value.

What Determines the Cost of a Hermetic Feedthrough

Several factors affect the price of a hermetic feedthrough, including:

- Material Choice: Feedthroughs made with glass, ceramic, or high-grade alloys cost more due to superior sealing, insulation, and durability.

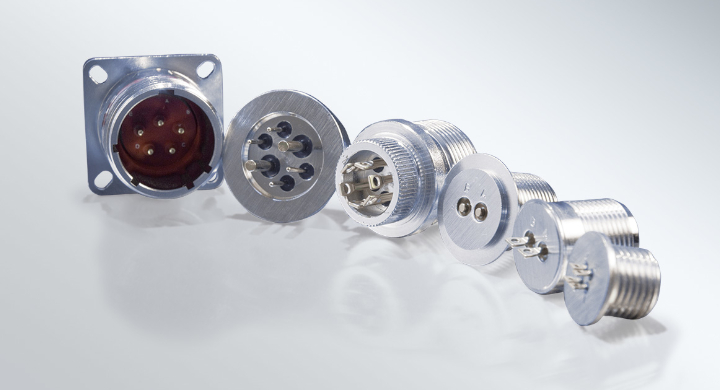

- Feedthrough Type: Single-pin, multi-pin, coaxial, or fluidic designs have varying complexity, affecting cost.

- Operating Specifications: Feedthroughs designed for high voltage, high frequency, high vacuum, or extreme temperature conditions require precision manufacturing.

- Customization: Custom configurations or non-standard sizes increase production complexity and cost.

PAVE Technology offers a wide range of hermetic feedthroughs, from standard models to fully customized solutions, allowing clients to choose options that meet their budget and technical needs.

Single-Pin vs Multi-Pin Hermetic Feedthrough Costs

- Single-Pin Feedthroughs: Typically the most cost-effective option, suitable for simple connections and less demanding applications.

- Multi-Pin Feedthroughs: Provide multiple electrical paths in a single sealed unit, reducing enclosure complexity but costing more due to manufacturing precision.

PAVE Technology provides both single-pin and multi-pin hermetic feedthroughs engineered for reliability while offering cost-effective solutions for various applications.

High-Performance and Specialty Feedthroughs

Hermetic feedthroughs designed for high-frequency signals, high-voltage applications, or extreme environmental conditions may carry higher prices due to the precision materials and manufacturing processes involved.

- Glass-to-Metal or Ceramic-to-Metal Seals: More expensive due to vacuum-tight sealing and thermal stability.

- Coaxial or RF Feedthroughs: Higher cost because of signal integrity requirements.

- Fluidic Feedthroughs: Cost varies based on the type of fluid or gas and pressure ratings.

PAVE Technology specializes in high-performance hermetic feedthroughs that meet demanding technical specifications without compromising quality.

How to Optimize Costs

- Assess Your Requirements: Choose only the features and specifications necessary for your application.

- Select Standard Sizes Where Possible: Standard feedthroughs reduce customization costs.

- Work with Trusted Suppliers: Brands like PAVE Technology provide reliable products that minimize failures, avoiding costly replacements or downtime.

- Consider Long-Term Reliability: Investing in high-quality feedthroughs reduces maintenance costs and extends system lifespan.

Conclusion

The cost of a hermetic feedthrough varies based on material, type, operating requirements, and customization. While high-performance and specialized feedthroughs may carry a premium, they ensure reliability, longevity, and safety in critical applications. By working with trusted brands like PAVE Technology, engineers and procurement teams can select feedthroughs that meet both technical specifications and budgetary needs.